December 2015

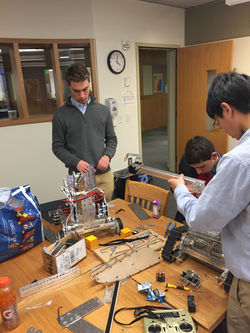

After learning a lot at the scrimmage, the team began to focus on our final robot design. PushBot was still a strong contender, and we continued practicing with it, both by improving its arm and refining the Autonomous Mode program. Mike and his team tried to perfect the harvester design, but were ultimately unsuccessful. Tiree started to work earnestly on his rotating arm design.

Daniel works on improving PushBot's gripping arm. |  Max hard at work programming. |  Dylan, Max and Maheep relaxing in the room. |

|---|---|---|

The original rotating arm design disassembled |  Tiree lost in thought. |  Mike working on Harvester. |

PushBot on the field |  The team at work. |  Tiree mounts the new rotating mechanism. |

With the competition quickly approaching, the team focused and settled on a final design: Centaur. The top half would be a rotating arm design based on the prototype developed by Tiree Walker and Troy Young. The bottom half of the robot would be the tank tread design developed by Mike Letterio. This design would allow us to climb the ramp as well as pickup and score with the game cubes.

Centaur's base, with the lazy susan mechanism for rotating. |  Sharan begins adding the arm, while Reed works on gearing. |  Mounting the arm on the base. |

|---|---|---|

Marc Frankel considers PushBot, while Reed works on Centaur. |  Sharan moves Centaur to the field, while Reed looks on. |  Tiree and Sharan working on Centaur |

Reed mounts the electronics. |  Mr. Brodie and Ben Williams evaluate Centaur's climbing capabilities. |  Reed and Ben working on Centaur |

Marc adjusts Centaur's wiring |  Reed, Dylan and Troy making final adjustments. |  Final field tape pattern. |

Dylan, Mike and Reed came in several times over Winter Break to put the finishing touches on Centaur. They tried to build a bumper in the front to help clear the debris on the field. Unfortunately, this made the robot too long and prevented it from climbing the ramp, so this idea was abandoned. They mounted all of the electronics, installed the servo for the gripper, and adjusted the gearing ratio on the arm.

Mike carefully measures the width for the new bumper. |  Mike and Dylan start to mount the electronics deck. |  A profile shot of the final design |

|---|---|---|

Reed drills mounting holes for the electronics shelf. |  Mr. Brodie advises Mike on the placement of marks for cutting. |  Reed files down the burrs from drilling. |

Mr. Brodie, Mike and Reed discuss design goals. |  Mr. Brodie, Mike and Reed use CNC software to machine the bumper. |